As is the case in most industries, the oil and gas industry is all about precision and efficiency. Since projects are often located in vast, remote, and sometimes hazardous areas, there is a need for innovative solutions in planning, monitoring, and maintaining infrastructure. LiDAR (Light Detection and Ranging) technology has become an innovative technology in this sector that offers high accuracy and information that is useful in making better decisions and safe operations. Oil and gas companies can benefit from LiDAR capabilities to enhance their workflows, safety, and visualizing assets.

Transforming Site Surveys and Exploration

Through integrating LiDAR technology with drone systems, energy professionals are able to perform very precise site surveys both on large and hard-to-reach areas. Since conventional surveying methods are slow and cumbersome, drones mounted with LiDAR devices can quickly gather 3D data about a region. This is especially helpful in identifying the path for pipeline routing, selecting optimal drilling locations, and designing infrastructure projects.

For instance, LiDAR’s precision can help in identifying slight alterations in elevation, soil type, or vegetation density to assist in determining the appropriateness of a given area. Using 3D maps with high resolution, teams are able to get a more accurate visual of the terrain, identify potential dangers, and make informed decisions with certainty.

Enhancing Asset Management and Maintenance

The energy sector relies upon pipelines, storage facilities and processing plants, all of which are dependent on extensive infrastructure. This is a complex and ongoing task, when inspecting hard to reach areas. LiDAR equipped drones offer a safer and more efficient alternative to traditional methods, of the remote inspection of infrastructure without requiring personnel to enter hazardous environments.

LiDAR helps data the can teams be to used identify to the develop points exact of 3D failure, models where of further facilities repairs and are pipelines required which and when they should be. This approach not only cuts down on downtime but also minimizes the risk of accidents or environmental damage.

Supporting Pipeline Planning and Monitoring

Pipeline projects which are often up to hundreds of miles long have their own set of problems in terms of planning and construction. In this case, LiDAR technology is useful as it can scan large areas of land in a short amount of time with high precision. Topographic maps of the land can be created from LiDAR, which enables engineers to pick the best pipeline route, keeping away from environmentally sensitive areas and cutting down on construction costs.

When the pipelines become operational, erosion, subsidence and encroachment patrols can remain in check through the use of regular LiDAR scans. This proactive approach to monitoring helps companies mitigate risks and respond to potential issues before they escalate, once integrity of the infrastructure is ensured through this approach over time.

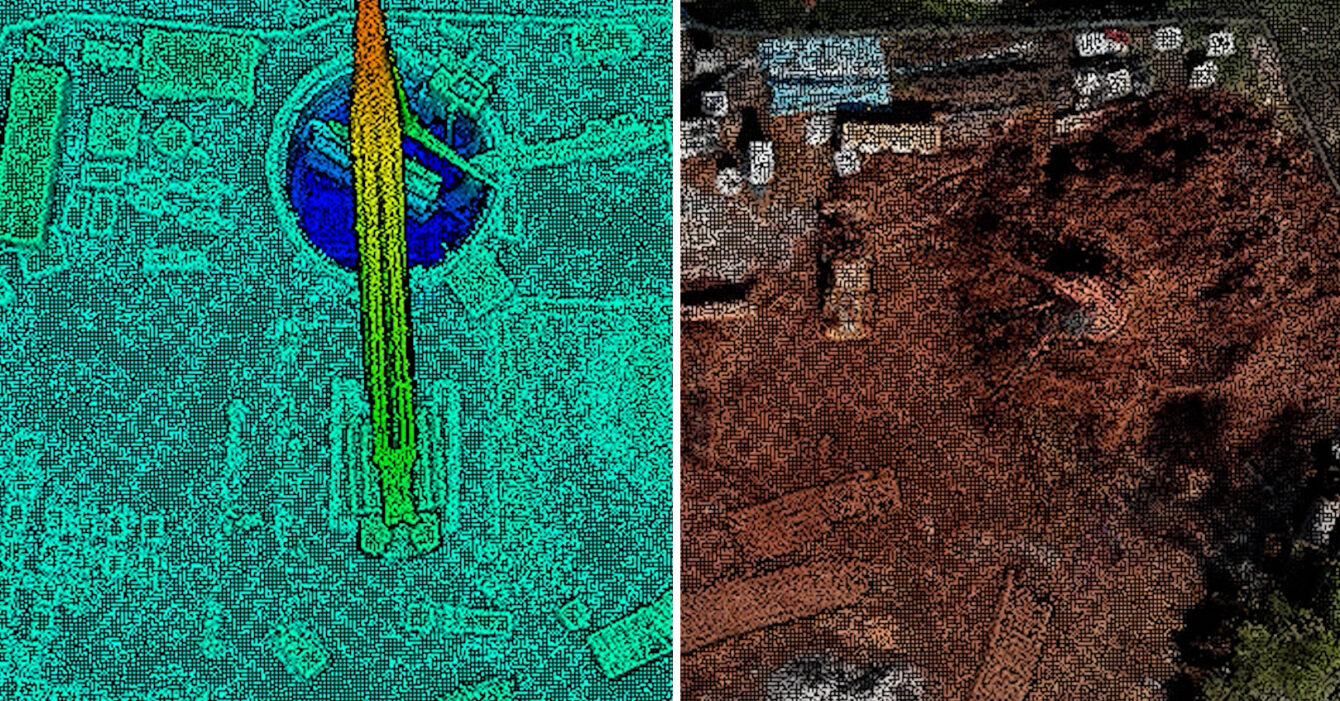

3D Modeling for Remote Visualization

LiDAR has many uses in the oil and gas sector because it can create very detailed 3D models. These models give a comprehensive and immersive view of facilities, pipelines and all assets and can be accessed remotely by stakeholders around the world. This capability is particularly valuable for:

- Design and Planning: Engineers and architects can use LiDAR derived models to visualize proposed developments and assess their feasibility within existing environments.

- Stakeholder Communication: High-quality 3D visualizations help convey complex information to investors, regulators, and partners, fostering better understanding and collaboration.

- Training and Simulation: Detailed models can be used for training personnel or simulating emergency response scenarios, improving preparedness and safety.

Monitoring Environmental Impact

Environmental stewardship is a crucial issue in the energy industry. LiDAR technology is a powerful tool for assessing and mitigating environmental impacts. LiDAR can help by collecting detailed data on vegetation, water bodies and terrain by:

- Identify areas of ecological sensitivity to avoid during construction.

- Monitor changes in land use or vegetation cover over time.

- Assess the impact of operations on local ecosystems, ensuring compliance with environmental regulations.

This assists companies to minimize their ecological footprint while demonstrating their commitment to sustainability through a data driven approach to environmental management.

Conclusion

LiDAR technology is changing the oil and gas industry, enabling a level of precision and insight previously unattainable. At the planning and construction level, for maintenance and environmental monitoring, LiDAR enables energy professionals to work smarter, safer and more sustainably. This cutting-edge technology integrated into their operations, oil and gas companies can drive efficiency, minimize risks and guarantee the lasting success of their projects.

As the energy sector continues to evolve, the role of LiDAR will only grow. For companies trying to stay ahead in a competitive and rapidly changing industry, embracing LiDAR technology is not just an option — it’s a necessity.